9 Primary Electric Vehicle Components – EV Parts & Its Functions

July 31, 2024 2024-08-22 18:319 Primary Electric Vehicle Components – EV Parts & Its Functions

9 Primary Electric Vehicle Components – EV Parts & Its Functions

What is Electric Vehicle (EV)

An electric vehicle (EV) is a type of vehicle that is propelled by electric motors using electrical energy stored in

batteries or another energy storage device, rather than relying on an internal combustion engine (ICE) that uses

fossil fuels. EVs are known for their potential to reduce emissions, improve energy efficiency, and offer a more

sustainable alternative to conventional vehicles.

Working principle of Electric Vehicle

- Energy Storage:

- Battery Pack: Stores electrical energy, typically using a lithium-ion batteries.

- Charging:

- External Power Source: The EV is plugged into a charging station, converting AC power from

the grid to DC power to charge the battery through the onboard charger.

- External Power Source: The EV is plugged into a charging station, converting AC power from

- Power Delivery:

- Power Electronics Controller: Manages the flow of electrical energy from the battery to the

electric motor, controlling speed and torque based on the driver’s input via the accelerator

pedal.

- Power Electronics Controller: Manages the flow of electrical energy from the battery to the

- Motor Operation:

- Electric Motor: Converts the electrical energy into mechanical energy to drive the wheels. Regenerative Braking:

- Energy Recovery: When braking, the electric motor acts as a generator, converting kinetic

energy back into electrical energy, which is stored in the battery.

- Driving:

- Acceleration and Cruising: The driver controls the vehicle’s speed through the accelerator,

with the controller adjusting the power flow to the motor for smooth operation. - Deceleration and Stopping: Releasing the accelerator or pressing the brake reduces power to

the motor and engages regenerative braking.

- Acceleration and Cruising: The driver controls the vehicle’s speed through the accelerator,

Types of Electric Vehicles

- Battery Electric Vehicles (BEVs): Fully electric vehicles that rely solely on battery power for

propulsion.

- Plug-in Hybrid Electric Vehicles (PHEVs): These have both an internal combustion engine

and an electric motor. They can be charged via an external source and can be operate in electric-only

mode for a certain range.

- Hybrid Electric Vehicles (HEVs): Combine an internal combustion engine with an electric

motor. The battery is charged through regenerative braking and the internal combustion engine, but

they cannot be plugged in.

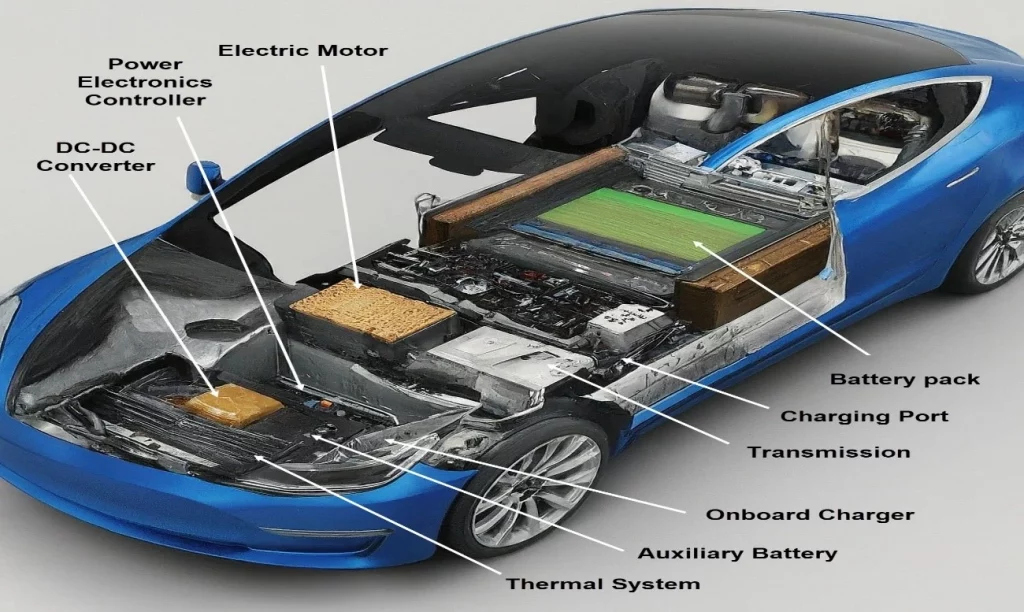

The key components of electric vehicle (EV) include:

1. Battery Pack:

The battery pack is the heart of an EV, storing the electrical energy that powers the car. Lithium-ion

batteries are the most common type of battery used in EVs due to their high energy density and long

lifespan.

- Composition and Structure

Cells: The battery pack consists of many individual cells. These cells can be of different

types, such as cylindrical, prismatic, or pouch cells. The most common chemistry used in EV

batteries is lithium-ion.

Modules: Cells are grouped into modules to make handling and management easier.

Pack: Multiple modules are then assembled into a battery pack, which includes cooling

systems, battery management systems (BMS), and structural supports. - Capacity and Range

Capacity: Measured in kilowatt-hours (kWh), the capacity of a battery pack determines how much

energy it can store. Higher capacity generally translates to a longer driving range.

Range: The actual range an EV can achieve on a full charge depends on various factors including the

vehicle’s efficiency, driving conditions, and battery capacity. - Charging

AC Charging: Using a standard home outlet or dedicated EV charging station. This is typically slower

and more suited for overnight charging.

DC Fast Charging: Provides much quicker charging and is available at specialized public charging

stations. It can recharge the battery to about 80% capacity in a short period. - Battery Management System

It monitors and manages the battery pack’s state of charge, temperature, health, and safety. Balances

the charge among individual cells to ensure optimal performance and longevity. The BMS is crucial for

the safe and efficient operation of the battery pack. It Monitors the state of charge (SOC) and state of

health (SOH) of the battery. Balances the charge among cells to ensure uniform performance and

longevity. Manages temperature through cooling and heating systems to keep the battery within the

optimal temperature range. Provides safety mechanisms to prevent overcharging, deep discharging, and

short circuits.- Types of Batteries

- Lithium-Ion Batteries

- Nickel-Metal Hydride Batteries

- Lead-Acid Batteries

- Solid-State Batteries

- Lithium Iron Phosphate (LiFePO4) Batteries

- Lithium-Sulphur (Li-S) Batteries

Nickel-Cobalt-Manganese (NCM) Batteries - Nickel-Cobalt-Aluminium (NCA) Batteries

- Types of Batteries

2. Electric Motor:

The electric motor is what propels the car. It converts the electrical energy from the inverter into

mechanical energy to turn the wheels. Some EVs use multiple electric motors, one for each axle, which

can provide all-wheel drive. It is one of the important components of electric vehicle.

- Types of Electric Motors in EVs

- Permanent Magnet Synchronous Motor (PMSM)

- Induction Motor (Asynchronous Motor)

- Brushless DC Motor (BLDC)

- Switched Reluctance Motor (SRM)

3. Power Electronics Controller:

The power electronics controller, often called the motor controller, is the brains behind the movement

in an electric vehicle (EV). It’s like the conductor of an orchestra, managing the flow of energy between

the battery and the electric motor for optimal performance.

- Inverter: Converts DC electricity from the battery to AC electricity if the electric motor

requires AC power. Essential for EVs with AC motors. - DC-DC Converter: Converts high-voltage DC from the battery pack to low-voltage

DC to power auxiliary systems such as lights, infotainment, and other electronics

4. Charging Port:

Allows the EV to connect to external power sources for charging. Compatible with various types of

chargers, including Level 1 (standard outlet), Level 2 (home and public charging stations), and Level 3

(DC fast charging). This is the connection point for charging the EV’s battery pack. There are different

types of charging ports, with SAE J1772 being the most common standard in North America and CCS

(Combined Charging System) being used in Europe and Asia.

- AC Charging Ports:

- Type 1 (SAE J1772):

➢ Usage: Primarily used in North America and Japan.

➢ Features: Suitable for Level 1 (120V) and Level 2 (240V) AC charging. - Type 2 (Mennekes):

➢ Usage: Common in Europe and other regions.

➢ Features: Supports single-phase and three-phase AC charging, offering higher power levels

compared to Type 1.

- Type 1 (SAE J1772):

- DC Charging Ports:

- CHAdeMO:

➢ Usage: Developed in Japan, widely used for DC fast charging.

➢ Features: Allows for rapid charging, typically up to 50 kW, with newer versions supporting

higher power levels.

- CHAdeMO:

- Types OF Charging Infrastructure:

- Public Charging Stations: Compatibility with various charging networks, enabling access to a wide

range of charging stations. - Home Charging: Installation of compatible charging ports for convenient home charging solutions,

often with smart charging capabilities. - Smart Charging: Integration with smart grids to optimize charging based on grid demand and energy

availability, potentially reducing costs and supporting renewable energy use

- Public Charging Stations: Compatibility with various charging networks, enabling access to a wide

5. Thermal System:

It Maintains optimal operating temperatures for the battery, motor, and other components. Ensures

efficient performance and longevity of the components. This system is essential for keeping the battery

pack, electric motor, and power electronics cool, as they can generate a lot of heat during operation. A

liquid cooling system is typically used, circulating coolant throughout the components and exchanging

heat with the outside air through a radiator.

- Types of thermal system (Cooling)

- Liquid Cooling Systems

- Air Cooling Systems

- Phase-Change Materials (PCMs)

6. Transmission:

Some EVs use a single-speed transmission, while others might have a multi-speed gearbox to

optimize performance and efficiency. Unlike gasoline-powered cars that use a multi-speed

transmission, EVs typically use a single-speed reduction gear. This is because electric motors

can deliver a wide range of torque (turning force) at all speeds.

- Types of EV Transmissions

- Single-Speed Transmission:

➢ Design: Simplest form, consisting of a fixed gear ratio.

➢ Advantages: Less complexity, lower cost, lighter weight, and reduced maintenance.

➢ Examples: Most mainstream EVs like the Nissan Leaf, Tesla Model S, and Chevrolet Bolt use

single-speed transmissions. - Multi-Speed Transmission:

➢ Design: Includes two or more gears to optimize power delivery.

➢ Advantages: Can improve efficiency and performance, particularly at high speeds or under

heavy loads.

➢ Examples: Porsche Taycan uses a 2-speed transmission for better acceleration and top speed. - Direct Drive:

➢ Design: The motor is directly connected to the drive shaft without a traditional gearbox.

➢ Advantages: Maximum simplicity and efficiency.

➢ Examples: Some concept vehicles and special applications may use direct drive systems.

- Single-Speed Transmission:

7. DC-DC Converter:

In an electric vehicle (EV), the DC/DC converter plays a crucial role in managing the electrical power flow

between different voltage systems within the vehicle. Here’s an in-depth look at the DC/DC converter in EVs:

- Function of the DC/DC Converter

- Voltage Conversion:

➢ High-Voltage to Low-Voltage: The primary function of the DC/DC converter in an EV is to

step down the high-voltage DC power from the main traction battery (typically several

hundred volts DC) to the lower voltage required by various auxiliary systems (usually 12V or

24V DC).

➢ Stable Power Supply: Ensures a stable and reliable power supply to systems such as lights,

infotainment, HVAC (Heating, Ventilation, and Air Conditioning), power windows, and other

electronics. - Support for Auxiliary Systems:

➢ Battery Charging: Charges the auxiliary battery (12V or 24V) that powers these systems when

the vehicle is operational.

➢ Backup Power: Provides backup power to essential systems in case of a fault or shutdown of

the main high-voltage system. - Isolation and Protection:

➢ Isolation: Electrically isolates the high-voltage system from the low-voltage system to prevent

potential electrical hazards and ensure safety.

➢ Protection: Monitors voltage levels and ensures that the output voltage remains within safe

limits, protecting the auxiliary systems from overvoltage or undervoltage conditions.

- Voltage Conversion:

- Components of the DC/DC Converter

- Converter Circuitry:

➢ Power Semiconductors: Typically uses MOSFETs (Metal-Oxide-Semiconductor Field-Effect

Transistors) or IGBTs (Insulated Gate Bipolar Transistors) to perform the voltage conversion

efficiently.

➢ Inductors and Capacitors: Components used to filter and smooth the output voltage, reducing

ripple and ensuring stable DC output. - Control and Monitoring Systems:

➢ Microcontroller or DSP (Digital Signal Processor): Manages the operation of the DC/DC

converter, monitors input and output voltage levels, and adjusts conversion as necessary.

➢ Sensors: Voltage and current sensors provide feedback to the control system to ensure proper

operation and protection. - Cooling System:

➢ Heat Sink or Cooling Fan: Depending on the power rating and design, the DC/DC converter

may incorporate a cooling system to dissipate heat generated during operation, ensuring

reliability and longevity.

- Converter Circuitry:

8. Onboard Charger:

An on-board charger (OBC) in an electric vehicle (EV) is a critical component that converts

the AC (alternating current) power from the grid into DC (direct current) power to charge the

vehicle’s battery. Here’s a detailed overview:

- Function and Importance

- AC to DC Conversion: The primary function of the OBC is to convert AC electricity

from a household or public charging point to DC electricity suitable for the EV

battery. - Voltage and Current Management: The OBC manages the voltage and current

supplied to the battery, ensuring it is charged safely and efficiently. - Battery Management System (BMS) Integration: The OBC works in conjunction

with the BMS to monitor the state of the battery, including temperature, state of

charge (SOC), and health.

- AC to DC Conversion: The primary function of the OBC is to convert AC electricity

- Types of On-Board Chargers

- Single-Phase OBC: Typically found in residential settings, capable of handling lower

power levels. - Three-Phase OBC: Used in commercial settings where higher power levels are

available, allowing for faster charging times.

- Single-Phase OBC: Typically found in residential settings, capable of handling lower

9. Auxiliary Battery:

It is typically a 12V battery used to power ancillary systems such as lights, wipers, and the

infotainment system when the main battery is not in use. A 12-volt auxiliary battery is also used in EVs

to power low-voltage accessories such as the headlights, infotainment system, and interior lights. This

is like the 12-volt battery found in gasoline-powered cars.

These EV components work together to ensure the efficient and effective operation of an electric vehicle,

providing a cleaner and more sustainable alternative to conventional internal combustion engine vehicles.

Future of Electric Vehicle

Electric vehicles (EVs) in India’s booming transportation sector. component of electric vehicle

- India’s EV Opportunity:

- Huge market: With a rapidly growing population needing transportation, India presents a massive

opportunity for EVs. - Shifting from fossil fuels: The rise in vehicles shouldn’t translate to increased dependence on oil,

aligning with India’s climate goals.

- Huge market: With a rapidly growing population needing transportation, India presents a massive

- Challenges and Solutions:

- Sustainable mobility: Achieving net-zero emissions by 2075 requires a multi-pronged approach,

including EVs, improved public transport, and infrastructure development. - EV infrastructure: Building a robust network of charging stations and domestic battery production are

crucial for large-scale EV adoption. - Expert consensus: Industry leaders acknowledge EVs as the future, but India needs to invest in

infrastructure and manufacturing.

- Sustainable mobility: Achieving net-zero emissions by 2075 requires a multi-pronged approach,

Overall, the future of EVs in India is promising, but overcoming infrastructure and manufacturing hurdles is

essential. By addressing these challenges, India can unlock its potential to be a leader in the EV revolution.

Conclusion

Electric vehicles (EVs) are revolutionizing transportation, offering a cleaner, more sustainable future. According to IEA’s global-ev-outlook-2024 report , the EV market is projected to reach $800 billion by 2027, driven by advancements in technology and increased government incentives. As key components like battery packs and electric motors advance, EVs become increasingly efficient and accessible. India’s potential in this sector is immense, but overcoming infrastructure challenges is crucial. For those pursuing a career in this field, check out this guide on building a successful career in the EV industry and prepare with these top 35 EV engineer interview questions and answers.

About i GET IT by Tata Technologies

i GET IT by Tata Technologies is online learning platform for mechanical engineers and designers. It has extensive 2000+ range of courses, 8+ job role certifications and coverage of 20+ domain topics that makes it a comprehensive hub for engineering education. By offering specialized certifications and personalized learning paths, we ensure that learners not only acquire knowledge but also develop expertise in their chosen fields.

For more tech tips and in-depth eLearning for Electric Vehicle, including this and new courses on other design solutions, please visit i GET IT . You can sign up and get a FREE Subscription to our informative Newsletter.

Related Posts

Advancement in Hole Wizard Tool | SolidWorks

Creating a MultiHole with Simple Hole Type in CATIA V5 R34

Best Design Engineer Courses for Mechanical Engineer By Tata Tech

Understanding Single Line Diagram – Meaning, Importance & Example

How to Use Corner Relief in Catia V5

Find

Categories

Latest Posts

Advancement in Hole Wizard Tool | SolidWorks

August 6, 2024How to use Swap Location Command in 3DEXPERIENCE | CATIA

August 5, 2024Popular Tags