What is Computer Aided Manufacturing (CAM)? [Detailed Guide]

June 27, 2024 2024-11-11 13:29What is Computer Aided Manufacturing (CAM)? [Detailed Guide]

What is Computer Aided Manufacturing (CAM)? [Detailed Guide]

Have you ever wondered how intricate parts for our favorite gadgets or the sleek bodies of cars are meticulously crafted? It might surprise you to know that behind the scenes, computer software plays a vital role in this process. This is the magic of CAM! In this detailed guide, we will delve into what is Computer-Aided Manufacturing (CAM), how it works, and the immense benefits it brings to the manufacturing industry. Buckle up and get ready to witness the fascinating intersection of technology and precision that shapes the world around us!

Table of Contents

What is Computer Aided Manufacturing (CAM)?

Computer-Aided Manufacturing (CAM) is the use of computer software and hardware to control and automate manufacturing processes. CAM systems typically work in conjunction with Computer-Aided Design (CAD) software, allowing manufacturers to seamlessly transition from designing a part to programming the machines that will produce it. Computer-Aided manufacturing software takes the digital design created in CAD and generates toolpaths and machining instructions based on parameters such as material properties, tool specifications, and manufacturing constraints.

CAM technology has revolutionized manufacturing by enabling complex geometries, rapid prototyping, and high levels of automation, leading to increased productivity, reduced lead times, and improved quality in various industries, including aerospace, automotive, medical, and consumer goods.

A step-by-step overview of the CAD to CAM process

1. Conceptualization and Design:

The process starts with conceptualizing the product or part that needs to be manufactured. This involves brainstorming ideas, creating sketches, and using CAD (Computer-Aided Design) software to create detailed designs. CAD software allows designers to create 2D and 3D models of the part or product.

2. CAD Modeling:

Once the initial design is conceptualized, it’s time to create a detailed CAD model using specialized software like AutoCAD, CATIA, NX, SOLIDWORKS, Inventor or Fusion 360. Designers use these tools to create precise geometries, define materials, specify tolerances, and incorporate features like holes, fillets, and chamfers.

3. CAM Programming:

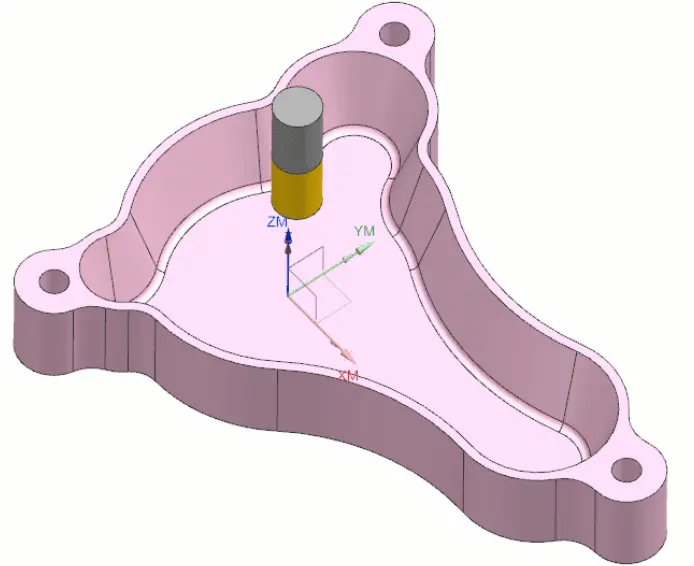

After the CAD model is finalized, the next step is to generate toolpaths using CAM software. CAM software takes the CAD model and generates the instructions necessary to control CNC (Computer Numerical Control) machines such as mills, lathes, or 3D printers. Computer-Aided manufacturing software allows users to define machining operations such as milling, turning, drilling, and threading, and specify parameters such as cutting speeds, feeds, and tool paths.

4. Toolpath Generation:

In this step, the CAM software generates toolpaths based on the geometry of the CAD model and the specified machining operations. The toolpaths determine the movements of the cutting tool or nozzle as it removes material from the workpiece to create the desired shape. CAM software optimizes toolpaths to minimize machining time, reduce tool wear and achieve the required surface finish.

5. Simulation and Verification:

Before machining begins, it’s essential to simulate the toolpaths to verify that they are free of collisions, ensure that the cutting tools are used efficiently, and confirm that the machining operations will produce the desired result. Computer-Aided manufacturing software provides simulation tools that allow users to visualize the machining process, detect errors, and make any necessary adjustments.

6. Post-Processing:

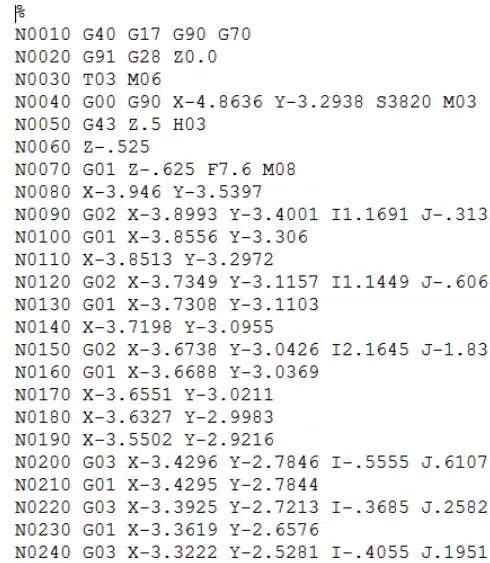

Once the toolpaths are generated and verified, the CAM software generates the machine-specific G-code instructions that will control the CNC machine. This G-code includes commands to move the machine axes, control spindle speed, and activate coolant systems. The G-code is then transferred to the CNC machine either directly or via a USB drive or network connection.

7. Setup and Machining:

With the G-code loaded into the CNC machine, the setup process begins. This involves loading the workpiece onto the machine, securing it in place, and loading the necessary cutting tools into the machine’s tool holders. Once the setup is complete, the machining process can begin. The CNC machine follows the instructions in the G-code to precisely cut away material from the workpiece according to the programmed toolpaths.

8. Quality Control:

Throughout the machining process, quality control measures are implemented to ensure that the finished parts meet the specified requirements. This may involve measuring critical dimensions using precision instruments such as calipers, micrometers, or coordinate measuring machines (CMMs), and inspecting the surface finish for defects.

9. Finishing Operations:

Depending on the requirements of the part or product, additional finishing operations such as deburring, sanding, polishing, or coating may be necessary to achieve the desired surface finish and appearance.

10. Documentation and Feedback:

Finally, documentation of the manufacturing process is created, including records of machining parameters, inspection results, and any deviations from the original design. Feedback from the manufacturing process is used to iterate on the design and improve future iterations.

The importance of CAD to CAM process in Manufacturing Industries

The CAD (Computer-Aided Design) to CAM (Computer-Aided Manufacturing) process is a crucial workflow in modern manufacturing. Here’s an overview

1. CAD: This is the initial step where engineers and designers create digital representations of the parts or products they want to manufacture. CAD software allows them to design and modify complex geometries with precision.

2. CAM: Once the design is finalized in CAD, CAM software takes over. Computer-Aided Manufacturing software translates the CAD design into instructions that control the machinery used in manufacturing. This includes CNC (Computer Numerical Control) machines, 3D printers, and other automated manufacturing equipment. CAM software generates toolpaths, specifies cutting parameters, and optimizes the manufacturing process for efficiency and accuracy.

The CAD to CAM process is crucial for several reasons:

1. Accuracy: By using digital models for both design and manufacturing, the CAD to CAM process ensures high levels of accuracy and consistency. This reduces errors and minimizes waste in production.

2. Complexity: Modern manufacturing often involves intricate geometries and intricate designs that would be difficult or impossible to produce without CAD and CAM technology. These tools enable manufacturers to create complex parts with precision and efficiency.

3. Speed: CAD to CAM automation speeds up the manufacturing process significantly. Once the design is finalized, CAM software can quickly generate toolpaths and manufacturing instructions, reducing lead times and time to market.

4. Cost-Effectiveness: By streamlining the manufacturing process and reducing errors, CAD to CAM technology helps manufacturers to save time and money. It optimizes material usage, reduces scrap, and increases overall productivity.

5. Flexibility: CAD to CAM technology enables manufacturers to quickly iterate on designs and respond to changes in market demands. They can easily modify digital models and update manufacturing instructions without significant downtime or retooling.

Applications of Computer-Aided Manufacturing (CAM) across industries

1. Automotive Industry:

– Design and Machining: CAM software is extensively used in the automotive sector to design and manufacture complex components such as engine blocks, cylinder heads, and transmission parts. These components often have intricate geometries that require precise machining processes.

– Tool Path Optimization: CAM enables engineers to optimize tool paths for milling, turning, and grinding operations. By doing so, manufacturers can minimize machining time, reduce tool wear, and improve overall efficiency.

– Prototype Production: CAM facilitates the creation of prototypes and molds for new vehicle designs. This capability allows automotive manufacturers to test and refine designs before mass production, saving time and resources.

2. Aerospace Industry:

– Precise Fabrication: In aerospace manufacturing, where precision is critical, CAM ensures the accurate fabrication of aircraft components like wings, fuselage sections, and engine parts. These components are often made from lightweight materials such as aluminum, titanium, and composite materials.

– Material Optimization: CAM software helps in simulating machining processes to optimize material usage and prevent issues like collisions or material deformation. This ensures the safety and reliability of aerospace parts, crucial for the integrity of aircraft structures.

– Safety Assurance: By detecting and preventing potential issues through simulation, CAM contributes significantly to ensuring the safety and reliability of aircraft components, ultimately enhancing aviation safety.

3. Medical Industry:

– High Precision Manufacturing: CAM plays a crucial role in the medical industry by manufacturing medical implants, prosthetics, and surgical instruments with high precision and customization. These products often require extremely tight tolerances to ensure compatibility with the patient’s anatomy.

– Customization: CAM enables the production of patient-specific implants based on medical imaging data. This customization ensures a perfect fit for each patient, improving surgical outcomes and patient satisfaction.

– Advanced Machining Techniques: CAM software supports multi-axis machining techniques, allowing the fabrication of complex medical devices and instruments with intricate geometries. This capability is essential for producing cutting-edge medical technologies.

4. Electronics Industry:

– Precision in PCB Manufacturing: CAM is indispensable in electronics manufacturing for producing printed circuit boards (PCBs) and electronic components with high precision and reliability. PCBs are the backbone of electronic devices, and their accurate fabrication is crucial for the performance and reliability of electronic products.

– Signal Integrity: CAM software facilitates the optimization of PCB layouts and routing paths to minimize signal interference and maximize space utilization on the board. This ensures that electronic devices meet strict performance requirements.

– Consistency in Fabrication: CAM generates tool paths for drilling, milling, and routing operations on PCBs, ensuring consistency and accuracy in electronic component fabrication. This consistency is essential for mass production of electronic devices.

5. Consumer Goods Industry:

– Efficient Customization: CAM enables manufacturers in the consumer goods industry to produce customized products efficiently while maintaining cost-effectiveness. This capability allows companies to cater to individual customer preferences and market demands.

– Rapid Prototyping: CAM supports rapid prototyping and iteration of product designs, allowing for quick adjustments based on customer feedback and market trends. This agility is crucial for staying competitive in fast-paced consumer markets.

– Automation for Mass Customization: CAM software assists in automating manufacturing processes for mass customization, enabling the production of personalized consumer goods at scale. This capability allows companies to achieve economies of scale while offering customized products to consumers.

6. Machining Industry:

– Optimized Machining Processes: CAM software is extensively used in machining operations such as milling, turning, and grinding to optimize tool paths and machining parameters. By optimizing these processes, manufacturers can minimize material waste and maximize cutting efficiency, leading to improved productivity and reduced production costs.

– Simulation for Quality Assurance: CAM supports the simulation of machining processes to identify potential issues and optimize machining strategies. By simulating these processes, manufacturers can ensure high-quality finished parts and minimize the risk of errors or defects.

– Enhanced Productivity: CAM facilitates the automation of machining processes, leading to enhanced productivity and efficiency in the machining industry. By automating repetitive tasks, manufacturers can free up resources and focus on more complex or value-added activities.

7. Tool and Die Industry:

– Design Precision: CAM plays a crucial role in designing and machining molds, dies, and tooling used in various manufacturing processes. These tools often require complex geometries with tight tolerances to ensure precise and reliable performance in production.

– Multi-Axis Machining: CAM software supports multi-axis machining techniques for machining intricate tooling components. This capability enhances productivity and accuracy in tool and die manufacturing, allowing manufacturers to produce high-quality tools with greater efficiency.

– Advanced Machining Technologies: CAM enables the use of advanced machining technologies such as high-speed machining and electrical discharge machining (EDM) in the tool and die industry. These technologies allow manufacturers to achieve intricate designs and high levels of precision in tooling production.

Advantages of CAM

1. Precision and Accuracy: CAM systems ensure precise control, minimizing human error and ensuring high accuracy in part production.

2. Efficiency and Productivity: Automation leads to faster production times and higher throughput, as CAM systems operate continuously without breaks.

3. Cost Savings: Despite initial investment, CAM reduces labor costs, material waste, and improves production efficiency, resulting in significant long-term savings.

4. Complex Machining: CAM handles intricate designs and geometries, enabling innovative product designs.

5. Reduced Lead Times: Streamlining from design to production shortens time-to-market, critical in fast-paced industries.

6. Flexibility and Customization: CAM systems are easily reprogrammed for different tasks, ideal for small batch production and prototyping.

7. Integration with CAD: Seamless integration with Computer-Aided Design (CAD) systems ensures accurate translation of designs into physical products.

8. Enhanced Safety: By automating dangerous tasks, CAM reduces the risk of injury to workers, improving workplace safety.

Disadvantage of CAM:

1. Cost of Implementation – Setting up CAM software and equipment can be expensive, especially for smaller businesses or individuals.

2. Hardware and Software Compatibility – Compatibility issues can arise between CAM software and the hardware it needs to control, such as CNC machines.

3. Maintenance and Upkeep – CAM systems require regular maintenance and updates to ensure optimal performance. This can add to the overall cost of using CAM technology.

4. Dependency on Technology – CAM systems rely heavily on technology, which means they are vulnerable to technical issues, software bugs, and cybersecurity threats.

Conclusion

Computer-Aided Manufacturing (CAM) stands at the forefront of the industrial revolution, driving efficiency, precision, and innovation across various sectors. From automotive to aerospace, CAM systems are integral to modern manufacturing, offering unparalleled advantages in terms of productivity, cost-efficiency, and quality. CAM’s ability to automate complex processes ensures consistent production standards and reduces human error, leading to superior product quality and faster turnaround times. As technology continues to advance, CAM will undoubtedly play an even more crucial role in shaping the future of manufacturing.

Innovations such as AI integration, real-time data analytics, and IoT connectivity will further enhance CAM capabilities, enabling smarter and more adaptive manufacturing environments. Embracing CAM not only fosters competitiveness but also paves the way for sustainable and intelligent production methodologies. By optimizing resource usage and minimizing waste, CAM contributes to eco-friendly manufacturing practices, aligning with global sustainability goals. As industries continue to evolve, CAM remains a cornerstone of modern production, ensuring that manufacturers can meet the demands of a rapidly changing world with agility and efficiency.

CAD/CAM Certification Courses by Tata Technologies

If you’re looking to deepen your understanding of CAM and its applications, consider exploring the comprehensive CAD/CAM certification courses offered by Tata Technologies education platform for engineers, i GET IT. These courses, designed by industry experts, provide a structured learning path, equipping you with the knowledge and skills to confidently navigate the exciting world of CAM. With i GET IT by Tata Technologies, you can transform your theoretical understanding into practical expertise, giving you a significant edge in today’s manufacturing landscape. Visit the i GET IT website today to explore the CAD/CAM certification courses and unlock the potential of CAM in your career.

Sayyam Tholiya

Related Posts

What is PLM? – Product Lifecycle Management [Detailed Guide]

Lead-Acid vs. Lithium-Ion Batteries: Key Differences & Best Uses

Top AutoCAD 3D Commands & Shortcuts with Examples

What is Engineering Mechanics? – Introduction 101

How to Create Stitch Weld in Weldments using Autodesk Inventor?

Find

Categories

Latest Posts

Popular Tags