Cam and Follower Mechanism – Types, Working & Application

March 18, 2024 2024-11-11 14:16Cam and Follower Mechanism – Types, Working & Application

Cam and Follower Mechanism – Types, Working & Application

In the intricate domain of mechanical engineering, where the demand for precision and efficiency is paramount, the cam and follower mechanism emerge as a dynamic and indispensable duo, serving a pivotal role in the conversion of rotary motion into reciprocating or oscillating motion. This ingenious pairing extends its influence across a spectrum of industries, ranging from automotive engineering to various manufacturing processes. In the ensuing exploration within this blog, we shall unravel the captivating intricacies of cam and follower mechanism, navigating through their fundamental principles, diverse types, and myriad applications.

Table of Contents

What is Cam and Follower?

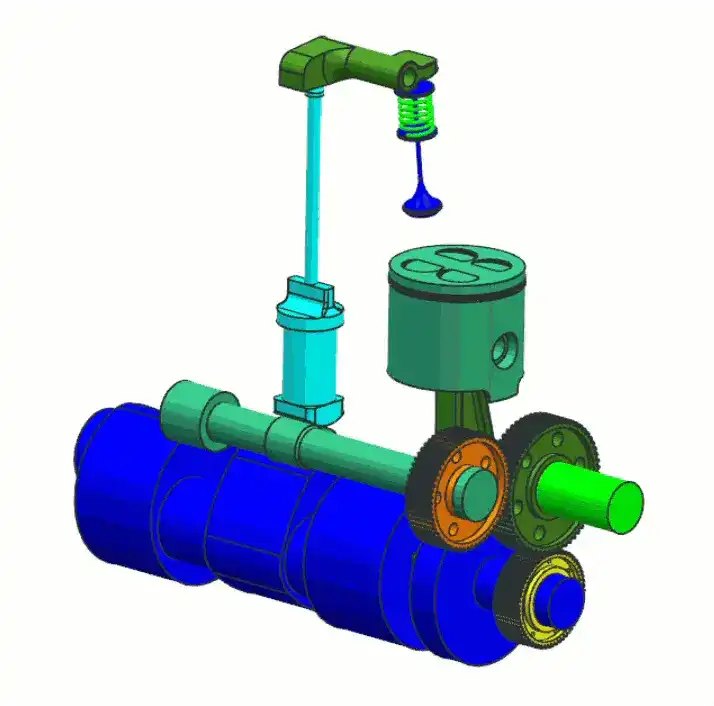

Let’s understand the basics of cam and follower mechanism. At the core of comprehending this mechanism lies the acknowledgment of its two essential components: the cam and the follower. The cam, possessing the ability to rotate or oscillate, acts as the driving force that conveys motion to the follower. Conversely, the follower reciprocates or oscillates in response to the cam’s movement, maintaining constant contact throughout. Aptly named the driven member, the follower then plays a crucial role in transmitting motion to achieve the desired output. In this symbiotic relationship, the cam assumes the role of the driving member, directing the mechanical run, while the follower faithfully carries out its part in translating this motion into a meaningful output.

Types of Cam and Follower

Now, we will discuss various cams and followers types. Firstly, we are going to classify the cams and then followers.

Types of Cams

Following are the types of cams: Disk or Plate Cams, Cylindrical Cams and Translating/Wedge Cams.

1. Disk or Plate Cams

Circular in shape, these cams are commonly used for simple applications where the follower's motion is linear. They are easy to manufacture and find applications in devices like printers and simple automation systems.

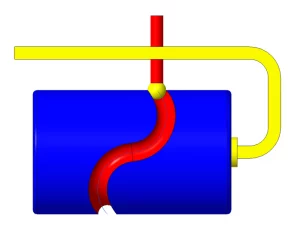

2. Cylindrical Cams

Cylindrical cams are shaped like a cylinder and are ideal for applications requiring more complex motion, such as oscillation. They offer versatility and are often found in internal combustion engines and machinery with intricate movement requirements.

3. Translating or Wedge Cams

These cams feature an inclined surface, providing a combination of linear and oscillating motion to the follower. Translating cams are widely used in packaging machinery and other systems requiring precise and controlled linear motion.

Types of Followers

Just as there are various types of cams, followers also can be classified based on various characteristics, including their shape, motion, and construction:

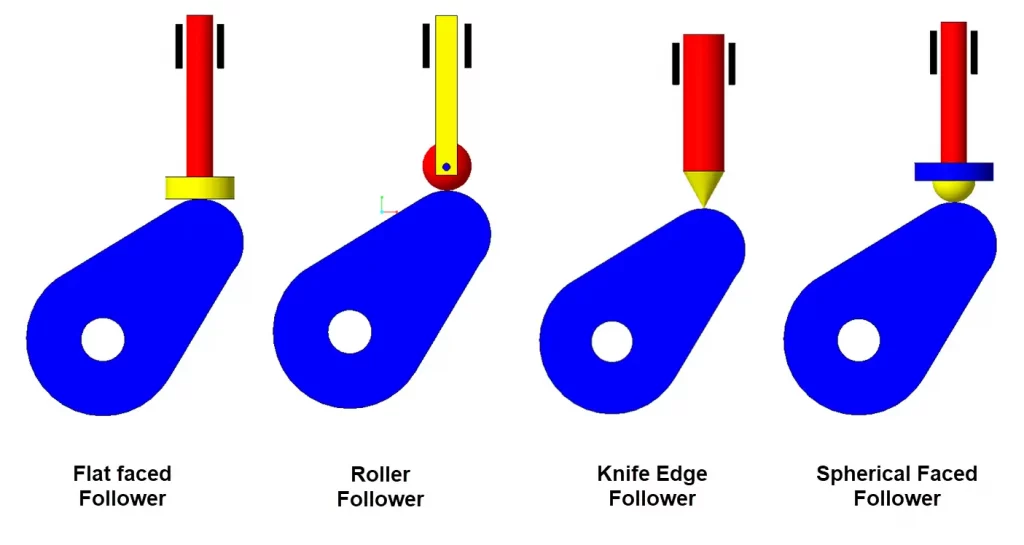

1. Based on shape

- Flat-faced Follower: This type of follower has a flat surface that makes contact with the cam. It is simple in design and often used in applications where simplicity and cost-effectiveness are essential.

- Roller Follower: The roller follower incorporates a cylindrical or spherical roller at its contacting end. This design minimizes friction and wear, making it suitable for high-speed and precision applications.

- Knife-edge Follower: This follower has a sharp edge that contacts the cam, offering a point of contact. It is used in situations where precise motion and minimal friction are crucial.

- Spherical-faced Follower: The follower has a spherical surface that contacts the cam. This design allows for better accommodation of misalignments and is often used in applications where flexibility is required.

2. Based on Motion

- Translating Follower: The follower moves parallel to the axis of rotation of the cam. This type is common in applications where linear motion is required.

- Oscillating or Swinging Follower: The follower swings about a pivot point during motion. It is suitable for applications where a swinging or pivoting motion is desired.

- Radial or Roller Follower: This type moves in a direction perpendicular to the axis of rotation of the cam. It is often employed when radial or outward motion is needed.

- Offset or Recessed Follower: The follower is offset or recessed from the axis of the cam, providing specific motion characteristics based on the offset distance.

3. Based on Compliance

- Rigid Follower: A rigid follower does not deform during motion, providing precise and predictable movement. It is suitable for applications where tight tolerances are critical.

- Flexible or Spring-loaded Follower: This type of follower has some degree of flexibility or incorporates springs to absorb shocks, and variations in the cam profile, or provide compliance in the system.

4. Based on Number of Contact Points

- Single-point Follower: This type has a single contact point with the cam, simplifying the design. It is often used in applications where simplicity and cost-effectiveness are priorities.

- Multi-point Follower: With multiple contact points, this follower type can distribute loads more evenly, reducing wear and improving stability in certain applications.

5. Based on Application

- High-speed Follower: Designed to withstand and perform well at high rotational speeds, this type is crucial in applications where rapid motion is required.

- High-force Follower: Constructed to handle and transmit high forces, this follower type is used in applications where strength and durability are paramount.

6. Based on Construction

- Solid or One-piece Follower: A one-piece construction simplifies manufacturing and assembly, often used in straightforward applications.

- Assembled or Multi-part Follower: Multiple interconnected parts can allow for more complex designs, adaptability, or incorporation of specific materials for enhanced performance.

Components of Cam and Follower

The basic components of a cam and follower system include:

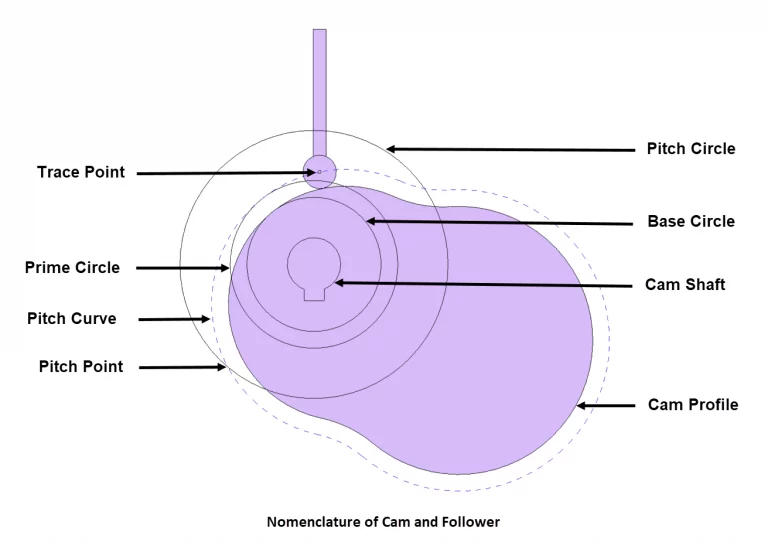

- Cam: The cam is a rotating element that typically has an irregular shape or profile. It is mounted on a shaft and rotates about its axis. The cam profile determines the motion of the follower.

- Follower: The follower is a component that is in contact with the cam's profile. It moves in response to the cam's motion. The follower can have various shapes, such as flat, roller, or knife-edge, depending on the application.

- Base Circle: The base circle is the smallest circle that can be drawn to the cam profile. It represents the position of the cam when it is not exerting any motion on the follower.

- Pitch Curve: The pitch curve is the curve formed by the traced points on the follower as the cam rotates.

- Pressure Angle: The pressure angle is the angle between the direction of motion of the follower and the normal to the pitch curve at a specific point. It helps in determining the force exerted on the follower by the cam.

- Dwell: Dwell refers to the portion of the cam profile where there is no motion, and the follower remains stationary.

- Lift: Lift is the maximum distance that the follower moves away from the base circle during one complete revolution of the cam.

- Stroke: Stroke is the total movement or displacement of the follower during one complete cycle.

- Cycle: A cycle refers to one complete revolution of the cam, including the rise, dwell, and return phases.

Applications of Cam and Follower Mechanism

The versatility of cam and follower mechanisms lends itself to a wide range of applications across various industries:

1. Automotive Engineering

Camshaft systems in internal combustion engines use cams and followers to control the opening and closing of valves, optimizing engine performance. The application of cam and follower knowledge in automotive engineering encompasses critical aspects of engine operation, fuel delivery, transmission, suspension, and braking systems. Understanding and optimizing these mechanisms are essential for enhancing vehicle performance, efficiency, and overall driving experience. Explore our Automotive engineering courses to master these skills.

2. Manufacturing Processes

Cam and follower systems are employed in machinery for precise cutting, shaping, and forming processes, ensuring accuracy in manufacturing.

3. Robotics

Robotic systems often utilize cam and follower mechanisms for controlled and precise movement in various applications, such as pick-and-place operations.

4. Textile Industry

Cam and follower systems are crucial in textile machinery for creating intricate patterns and designs in fabrics during the manufacturing process.

Conclusion

As we continue to push the boundaries of mechanical engineering, cam and follower systems remain at the forefront of innovation, inspiring the next generation of engineers to drive progress and shape the future. For those intrigued by the complexities of cam and follower mechanisms, delving deeper into core mechanical engineering courses can unlock a wealth of knowledge and opportunities. Aspiring engineers can gain the expertise and skills needed to tackle real-world engineering challenges, from optimizing cam profiles for efficiency to designing innovative follower mechanisms for cutting-edge applications.ourney to upskill today!

Should you have any inquiries, feel free to contact us at iproducts@tatatechnologies.com or igetitsupport@tatatechnologies.com for assistance.

About i GET IT

i GET IT by Tata Technologies is an eLearning solution platform, tailored to enhance engineers’ proficiency in utilizing today’s premier MCAD (Mechanical Computer Aided Design) applications and refining design skills.

For additional tech insights, explore our tech blogs. Sign up now and receive a complimentary subscription to our informative newsletter.

Embark on your journey to upskill today!

Should you have any inquiries, feel free to contact us at iproducts@tatatechnologies.com or igetitsupport@tatatechnologies.com for assistance.

Sayyam Tholiya

Related Posts

What is PLM? – Product Lifecycle Management [Detailed Guide]

Lead-Acid vs. Lithium-Ion Batteries: Key Differences & Best Uses

Top AutoCAD 3D Commands & Shortcuts with Examples

What is Engineering Mechanics? – Introduction 101

How to Create Stitch Weld in Weldments using Autodesk Inventor?

Find

Categories

Latest Posts

Popular Tags